The Results of a Study of Russian Entrepreneurs’ Digital Activity Were Discussed at a Joint EC/OECD Workshop

Experts from the ISSEK Centre for Business Tendencies Studies (CBTS) presented the results of a pilot project to measure digital activity of Russian industrial and retail companies at the 9th Joint EC/OECD Workshop (14-15 November 2019, Paris, France).

The CBTS staff members Ludmila Kitrar and Inna Lola presented the report ‘Digital Activity of Russian Enterprises: First Results of Pilot Surveys’.

To compensate for the obvious lack of statistical data about the digitisation level of the national economy, in 2018 and 2019 the CBTS team conducted pilot surveys of business trends and entrepreneurs’ digital activity.

The project group analysed the opinions and intentions of direct participants in the digitisation process: top managers of 1,150 manufacturing companies and 700 retail organisations. During the polls they were asked to assess the level and intensity of various digital technologies’ usage, along with the related risks, challenges, barriers, potential advantages, and future prospects for implementing innovative solutions.

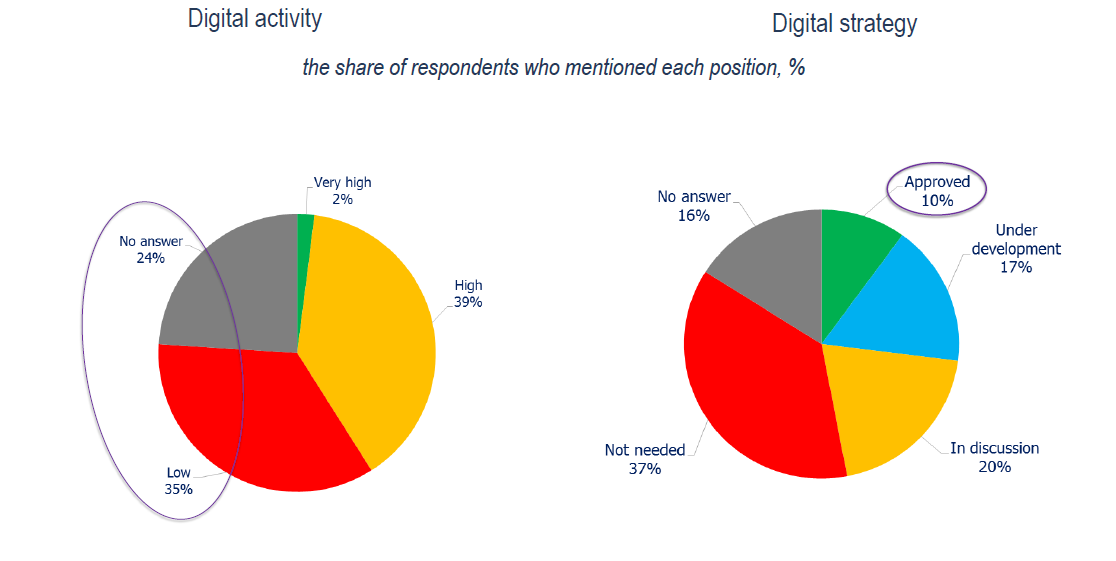

As the first results of the pilot survey indicate, in 2018 the digital agenda played a significant role in companies’ development, though many digital transformation projects still remained at the preparation stage requiring serious investments and improvements. Only one in ten surveyed companies had an approved digitisation strategy. Though more than 40% of the industrial enterprises’ managers assessed the level of their companies digital activity as high or very high, almost the same number of the respondents held the opposite opinion (Fig. 1).

Figure 1. Digitisation: strategy and implementation

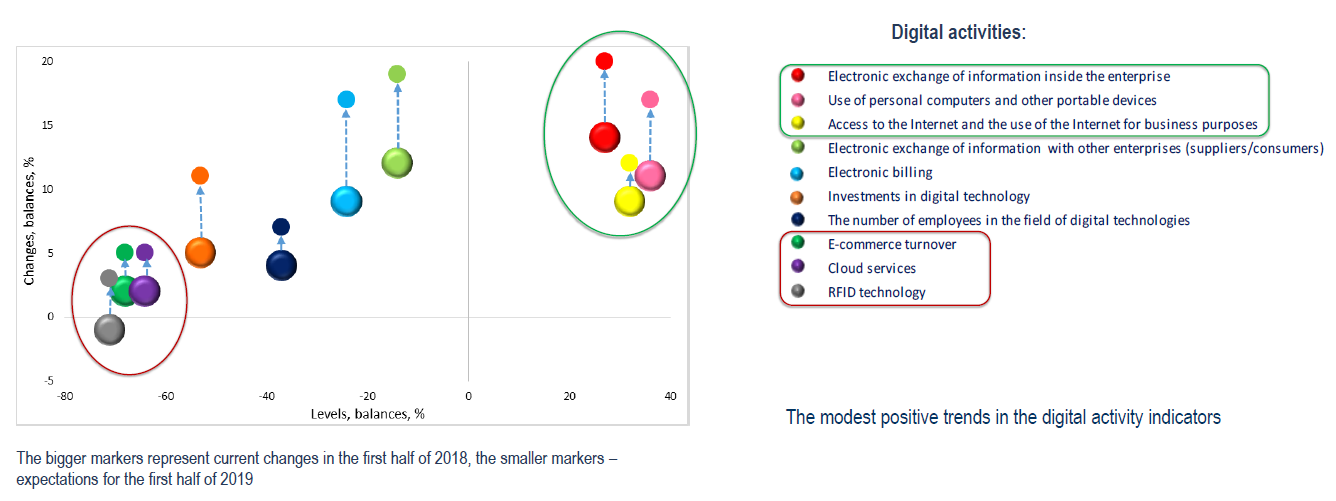

Despite the moderately positive trends in the dynamics of the main digital activity indicators, the ‘first wave’ technologies (electronic data exchanges, use of the internet and personal computers) had the highest growth rates (Fig. 2).

Figure 2. Application of digital technologies in manufacturing

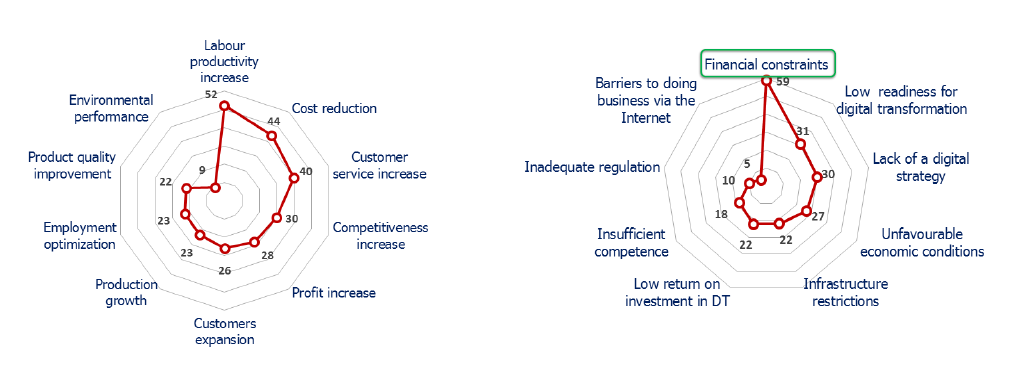

Most of the entrepreneurs (60%) believed lack of financial resources was the main barrier hindering digital transformation in manufacturing.

Entrepreneurs expected that investing in digital technologies would lead to increased labour productivity, reduced production costs, and improved customer service. The fact that for the ‘dirtiest’ industries, chemical and petrochemical ones, reducing the environmental impact of production was the main expected result of investing in digital technologies, was encouraging (Fig. 3, left graph).

Figure 3. Expected positive effects of applying digital technologies, and factors hindering digital transformation

The CBTS team intends to continue the work on this project and expand the range of questions. E. g. the 2019 pilot survey included a block of questions about the use of digital technologies to increase environmental efficiency of production, and the development of a green growth model in the region. Plans for 2020 include developing an algorithm for calculating composite digitisation indicators and, on their basis, designing a ranking system for industrial enterprises with various technological levels to measure their digital inequality.